Leonova Diamond IS

Leonova Diamond IS is the most advanced ATEX/IECEx-certified instrument on the market. With three-channel vibration measurement and a large color display, it provides a unique combination of sophisticated technologies and usability in a single portable instrument.

Zone 0 - 1 - 2 compliance for advanced condition monitoring

The instrument is built to withstand harsh environmental conditions. Heavy industries with intrinsic safety requirements, such as the refinery, mining, or oil and gas industries, are challenging environments. The instrument complies with the strictest ATEX/IECEx standards and thus can be used in zones 0 - 2.

Maximum flexibility with vibration analysis and SPM HD

Leonova Diamond IS offers the strongest combination of measuring techniques available. Three-channel vibration measurement (DC to 40 kHz), HD Order Tracking, sophisticated analysis, and the SPM HD technique for condition monitoring of rolling element bearings (1-20 000 rpm range) provide maximum flexibility for detecting machine faults.

Sophisticated analyzer with scalable functionality

The instrument is an excellent choice where a full range of measuring techniques and high analytical power is required to monitor plant equipment.

Based on a scalable system, Leonova enables customized solutions where additional functionality can be added as required.

ENGINEERED FOR PERFORMANCE

EMBEDDED INTELLIGENCE

PRODUCTIVITY AND EFFICIENCY

LOOKING FOR THE STANDARD VERSION?

By clicking “Submit”, you agree that your message and personal details will be sent by email to relevant recipient(s) at SPM Instrument. You hereby also agree that SPM Instrument and its subsidiaries will have access to the information you have provided and that these data will be stored on our email server. The data will not be saved in any other way. We will not use this information to contact you about matters other than those specified in your request. We will not share your information with third parties.

Features

The instrument includes the high-definition shock pulse method SPM HD® for bearing condition and advanced three-channel vibration analysis for general machine condition and many more features, see below.

Bearing and lubrication condition

Note: Also read about HD ENV® (below) for bearing monitoring.

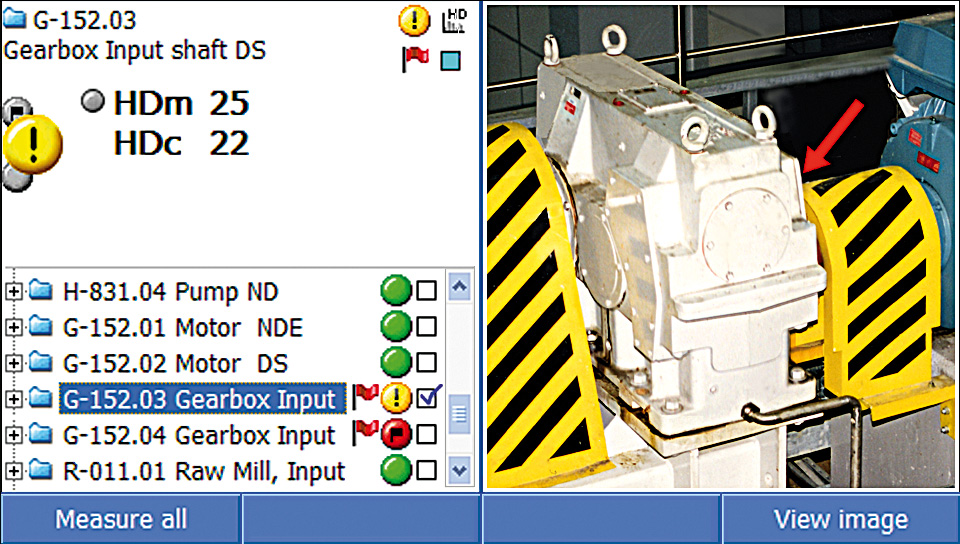

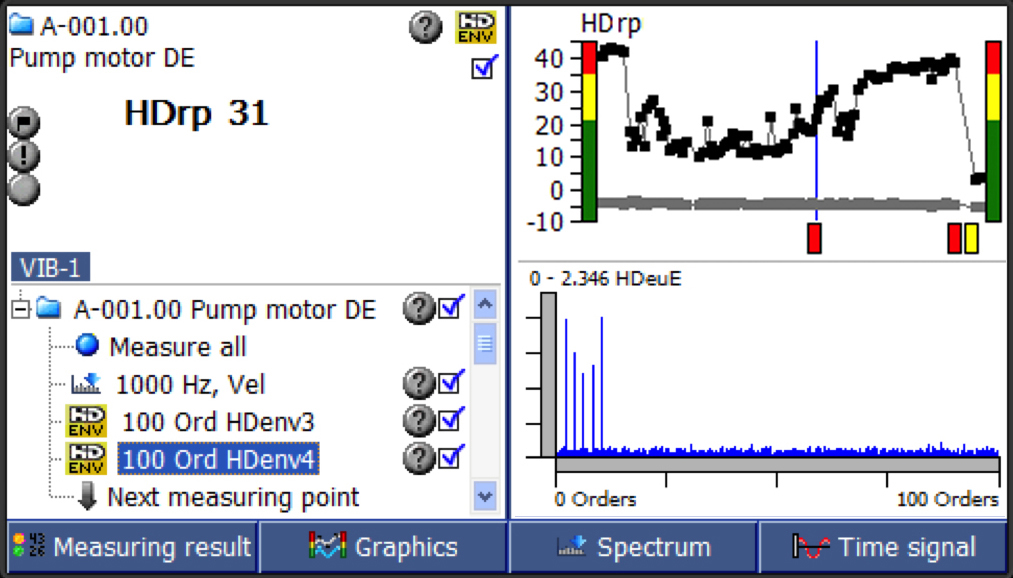

The SPM HD® Method (HDm/HDc)

The SPM HD® method is a patented further development of the Shock Pulse Method (SPM) in being less sensitive to interference from other signals and therefore unique in its ability to measure from very low rpm (0.1 - 20.000 RPM range). SPM HD is used for fast, easy, and reliable diagnosis of the operation condition of rolling element bearings.

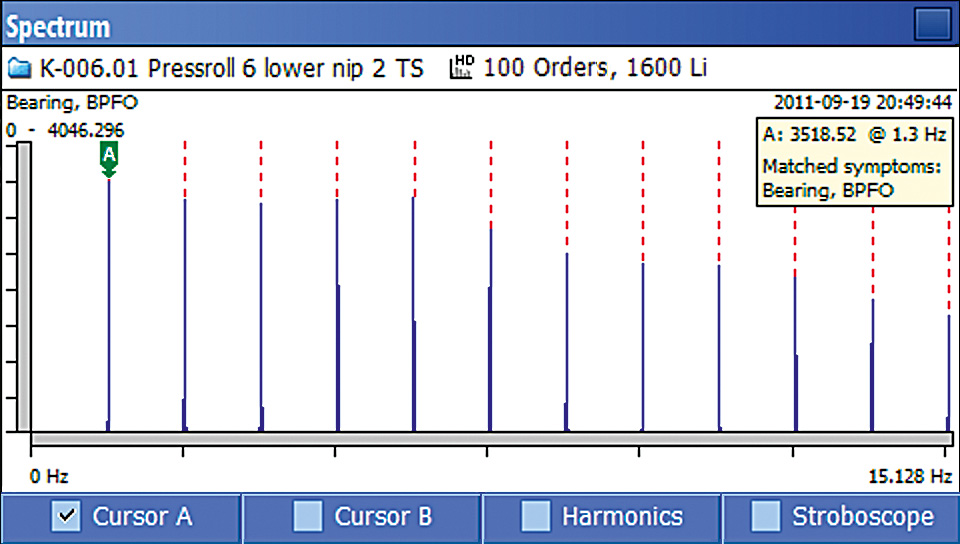

SPM Spectrum™

SPM Spectrum™ is based on extraordinary signal quality and 24 bit A/D conversion that provides razor-sharp resolution and helps determine where a possible bearing damage is located with very high precision.

dBm/dBc

The original Shock Pulse Method is based on dBm/dBc that counts the rate of incoming shock pulses per second and provides one value for the shock carpet level and one value for the maximum level (peaks).

LR/HR

The LR/HR method was developed from the original Shock Pulse Method for condition diagnosis of rolling element bearings and allows a precision analysis of oil film condition in the rolling interface.

Vibration analysis

The HD ENV® technique

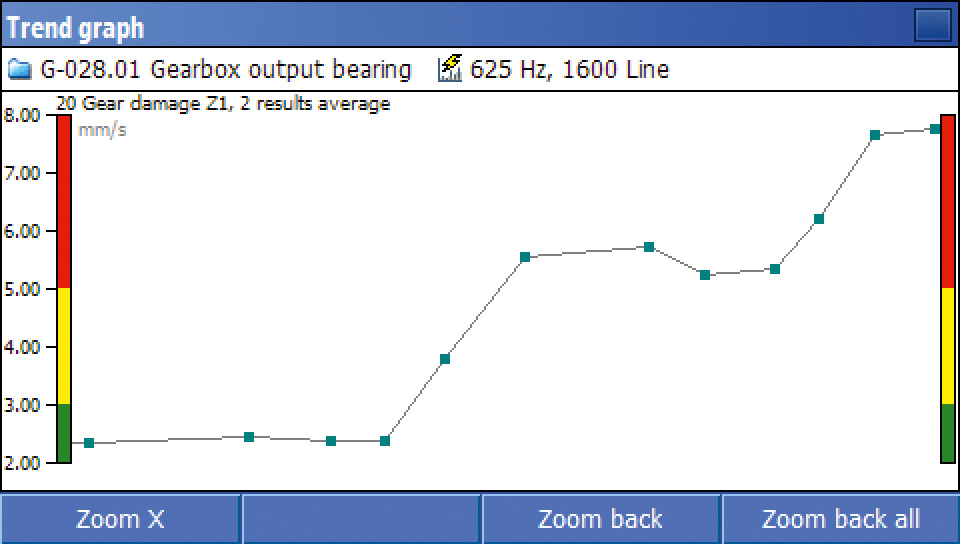

HD ENV® is a patented enveloping technique used for early detection of impact-related events such as gear and bearing damage. A number of predefined filters are available for easy selection; each designed to detect damages in different failure stages. The method utilizes cleverly engineered algorithms for digital signal processing to obtain optimal data for trending purposes.

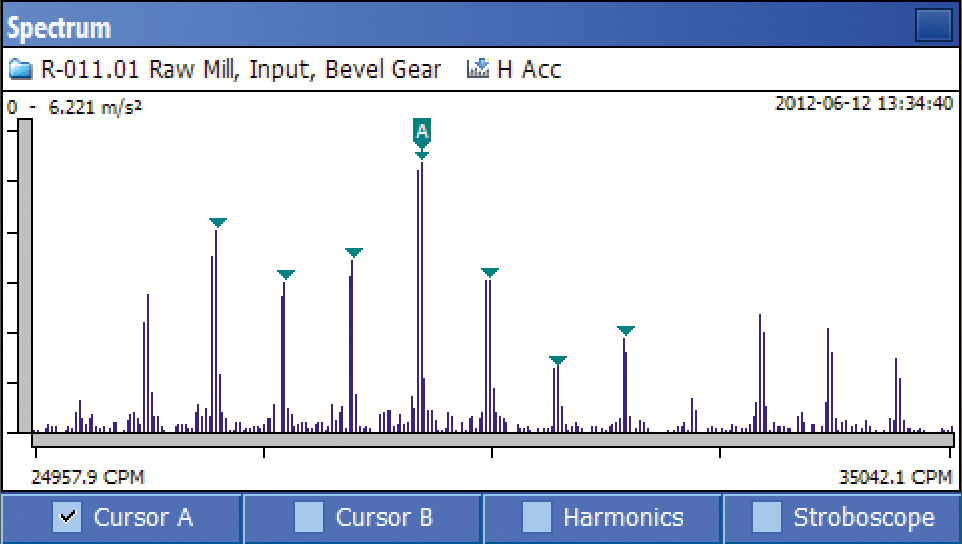

Vibration Severity plus FFT Spectrum

Measurement of vibration velocity, acceleration, and displacement (0-40kHz frequency range) according to the latest ISO 10816 standards helps to diagnose general machine condition. In addition to the RMS vibration readings, the instrument displays an FFT spectrum, where symptoms of imbalance, misalignment, and structural weakness are easily identified.

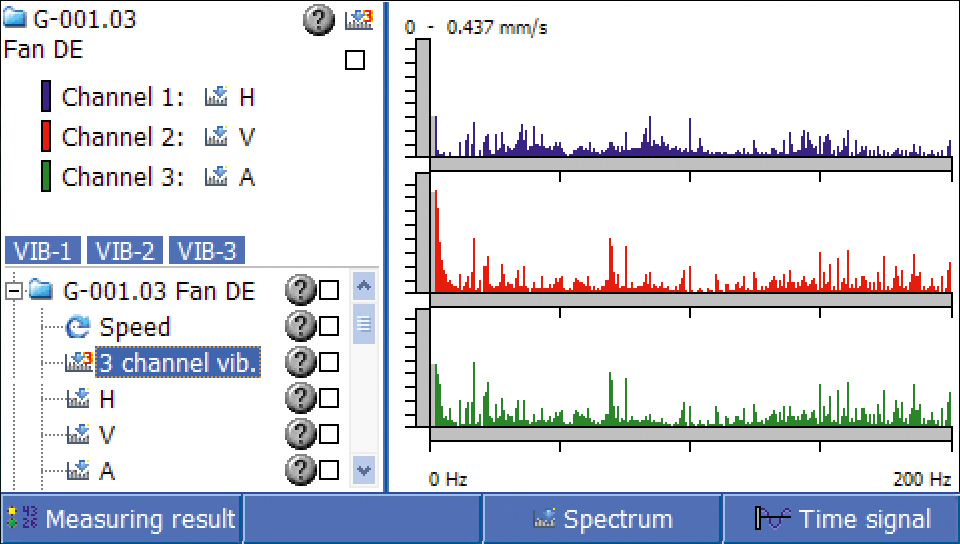

Three-channel vibration analysis

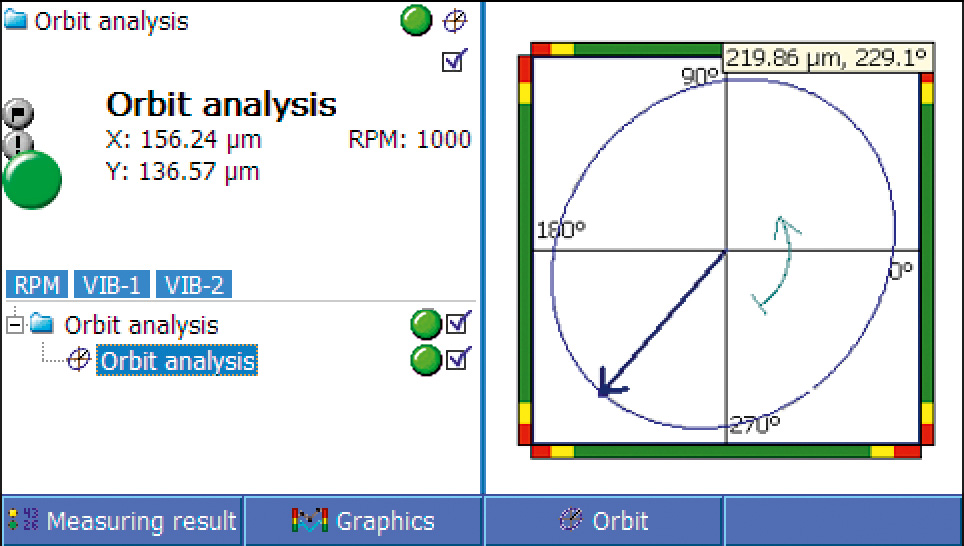

Three-channel vibration measurement allows you to study machine movement in three dimensions by observing the difference of the phase angles measured on the three channels. The three channels measure simultaneously, which means fast operation and rapid evaluation of assignments.

EVAM

The EVAM (Evaluated Vibration Analysis Method) measuring technique produces up to 25600 line spectrum with true zoom, provides ready-made machine 'fault symptoms' as well as trending.

Corrective maintenance

Dynamic balancing

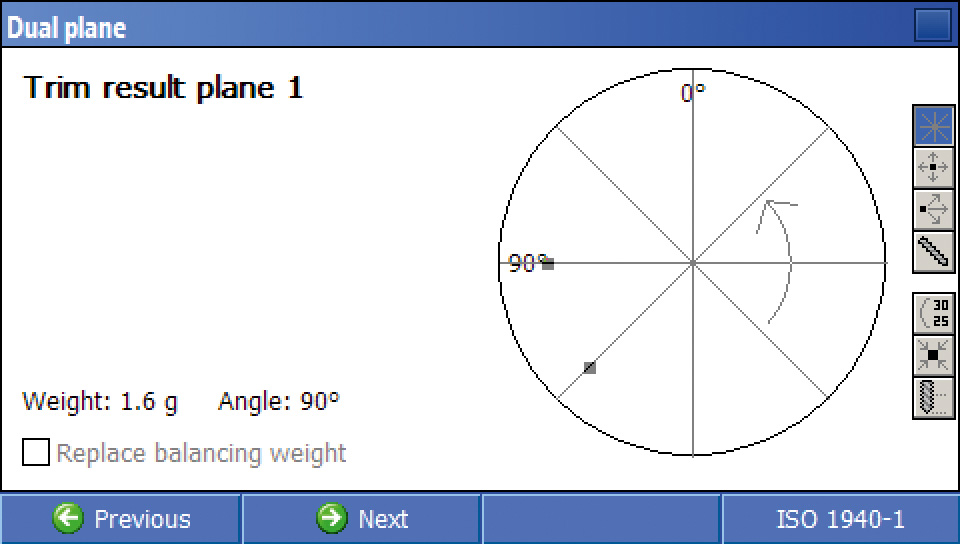

Field rotor balancing in single and dual plane according to ISO 1940-1 standard with an initial vibration measurement guiding the user through a balancing procedure with suggestions for correcting the imbalance.

Order tracking

HD Order tracking

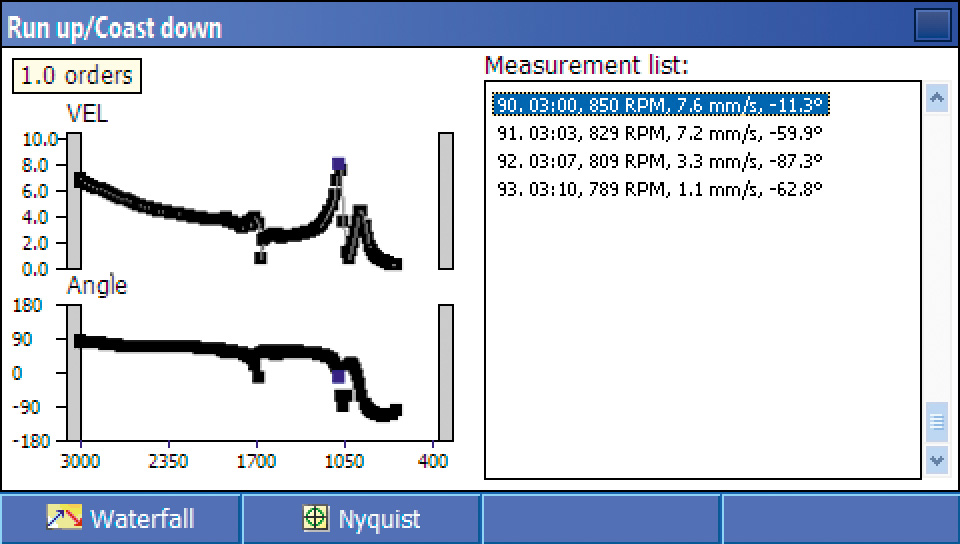

On machinery operating under variable speed, vibration analysis with HD Order Tracking provides reliable data and crystal clear measuring results even when RPM varies greatly during the course of measurement. Order tracking is applicable in a very wide RPM range, from just a few to thousands of revolutions per minute.

Technical overview

The intrument is lightweight, ergonomic, and easy to operate. Load measuring rounds to Leonova from the PC, then simply measure and save. All input data is pre-programmed. You get an instant condition evaluation on a green-yellow-red scale.

The instrument will deliver long working life under the toughest, most demanding circumstances. Leonova Diamond IS comply with the strictest ATEX/IECEx standards and thus can be used in zones 0 - 2.

Ex marking

Gas: II 1G Ex ia IIC T4 Ga, Ta -20°C to +50°C

Mining: I M1 Ex ia I Ma, Ta -10°C to +50°C

Instrument

Dimensions: 297x130x69 mm

Weight: 1005 g

Display: TFT colour, 480x272 pixels, 4.3 inch widescreen, adjustable backlight

Housing: Carbon-fiber-reinforced enclosure IP65

Instrument modules

To obtain the optimal performance range and instrument price, Leonova Diamond users can select between two alternatives of sale, unlimited and limited use. Unlimited and limited functions can be combined at will. Platform functions are always of unlimited use.

PLATFORM – unlimited use

- SPM HDm/HDc and/or LR/HR

- RMS vibration, ISO 2372

- Speed measurement

- Temperature measurement

- Stethoscope function

- Automatic recording, up to 50 hours

- Time signal recording

- Checkpoints, free text

- Recording of vocal comments

- Supports 2-channel simultaneous vibration measurements

- Supports up to 12 800 lines, 20 kHz

Functions for unlimited or limited use

Unlimited and limited functions can be combined at will.

- SPM HD Expert, time, and frequency domain analysis

- Shock pulse method HDm/HDc

- Shock pulse method dBm/dBc

- Shock pulse method LR/HR

- SPM Spectrum

- Vibration ISO 10816 with spectrum

- Vibration ISO 20283-5

- Orbit analysis/Shaft centerline plot

- 3-channel simultaneous vibration

- Vibration Expert

- HD Order Tracking

- Time signal and 25 600 lines, 40 kHz

- HD ENV

- EVAM evaluated vibration analysis

- Post trigger

- Run up/coast down

- Bump test

- Frequency Response Function (FRF)

- Vibration Advanced

- HD Order Tracking

- Time signal and 12 800 lines, 20 kHz

- HD ENV

- FFT with symptoms

- Post trigger

- HD Analysis

- Vibration Expert

- SPM HD Expert

- Balancing, single, and dual plane

Accessories

Transducers

Leonova Diamond IS can be used with vibration-, shock pulse- or DuoTech transducers for explosive environments, designed to withstand the rigors of industrial environments.

The transducers are available in an array of mounting options; magnet foot, quick connector, or fixed installation – choose what's most practical for your needs.

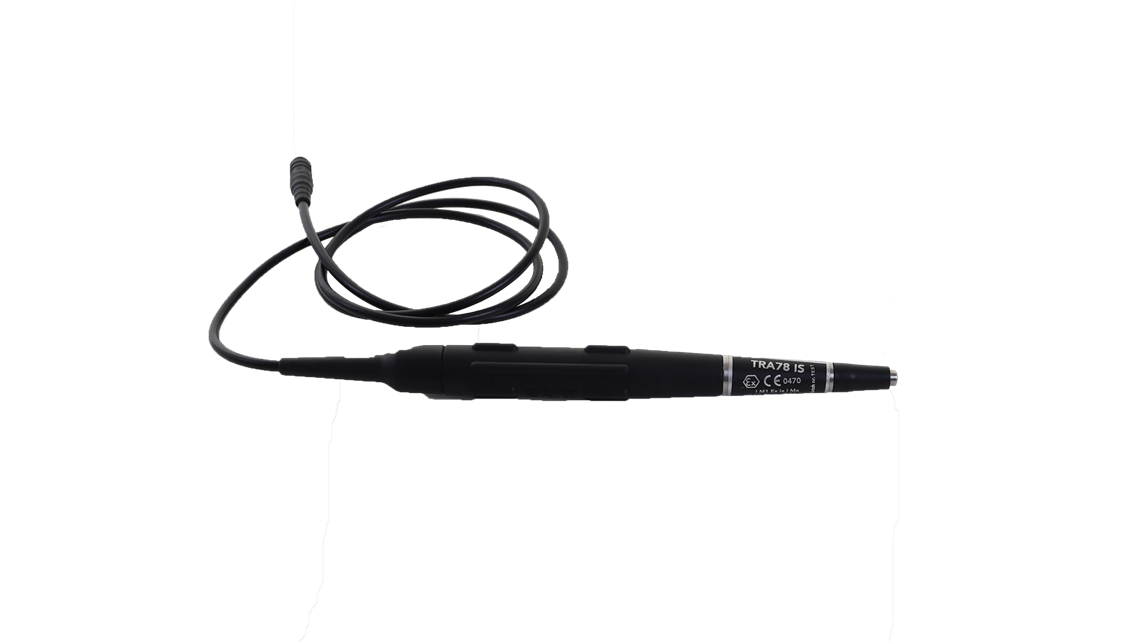

Handheld probe

The handheld shock pulse transducer with a probe is perfect for use together with SPM's handheld Ex instruments in a potentially explosive atmosphere. The probe tip is spring-loaded and moves within a sleeve made of chloroprene rubber (neoprene) and tolerates surface temperatures up to 110 °C (230 °F). The probe is classed IP65.

Combined tachometer and temperature probe

The tachometer and temperature probe for potentially explosive atmospheres is used for optical or contact measurement of the rate of rotation and for contact measurement of peripheral speed. It also has a built-in temperature sensor for measurements between −20 to +300 °C.

Headset with microphone

We also offer a comfortable headset (approved for use in potentially explosive atmospheres – except for zone 0) with a microphone for Leonova Diamond IS and Leonova Emerald IS, providing excellent sound reproduction even in noisy environments. The headset is equipped with a microphone for voice recording of comments to the measuring points. Connection cord made out of soft spiral polyurethane with a 6.3 mm stereo plug. An adapter must be used since the audio jack in the Leonova IS instruments is 3.5 mm. Choose between a headset with a headband, neckband, or with helmet brackets.

Handy case for your entire Leonova Diamond IS kit

This carrying case, made from the conductive material skai, is specially designed for transporting measuring instruments in explosive environments. The bag reliably prevents electrostatic charge and divert already existing charges. The soft case comes with easily customizable modular inserts and is provided with a shoulder belt for easy and hands-free movement.

Dimensions: 37x20x27 cm (14.5x7.9x10.6 in).